What are the differences between SMD, DIP, COB, and GOB LED screens?

The terms SMD, DIP, COB, and GOB refer to different technologies used in LED screens, each with its own characteristics and applications:

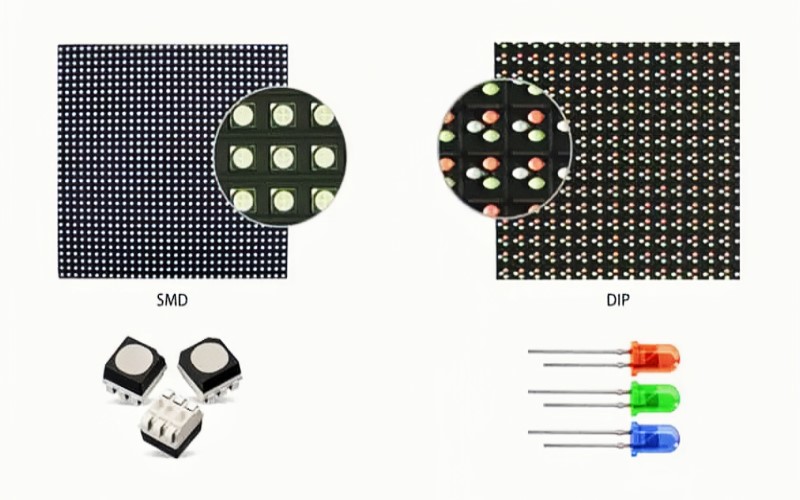

SMD (Surface Mount Device) LED Screen:

SMD LEDs are the most commonly used in modern LED screens.

They consist of three LED chips (red, green, and blue) packaged together as a single pixel.

SMD LEDs are smaller in size, allowing for higher pixel density and thus higher resolution screens.

They generally offer better color accuracy, wider viewing angles, and are more energy-efficient compared to older technologies like DIP.

DIP (Dual In-line Package) LED Screen:

DIP LEDs are older technology where each pixel is made up of three individual LED bulbs (red, green, and blue).

They are larger in size compared to SMD LEDs, which limits the pixel density and resolution.

DIP screens are more robust and can emit brighter light, making them suitable for outdoor displays where high brightness is required.

They have narrower viewing angles and consume more power compared to SMD LEDs.

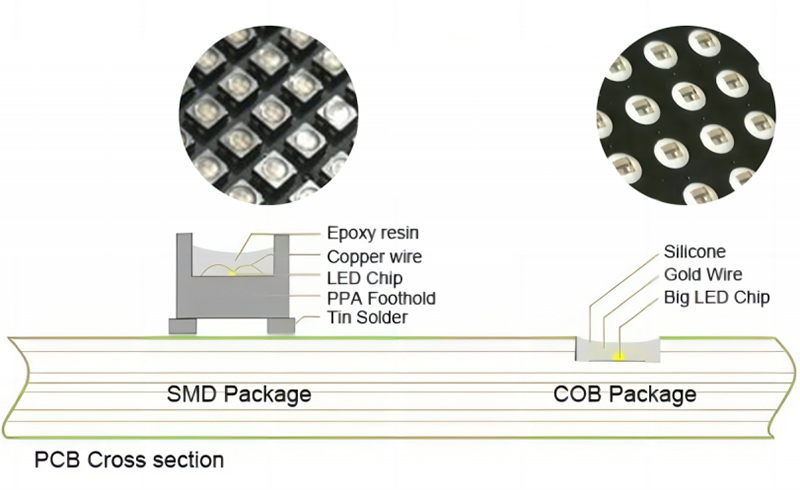

COB (Chip-on-Board) LED Screen:

COB technology involves mounting multiple LED chips directly onto a substrate to form a single module.

It eliminates the individual LED packaging found in SMD and DIP, resulting in a higher packing density and improved thermal management.

COB LEDs are often used in high-power applications where brightness and efficiency are critical.

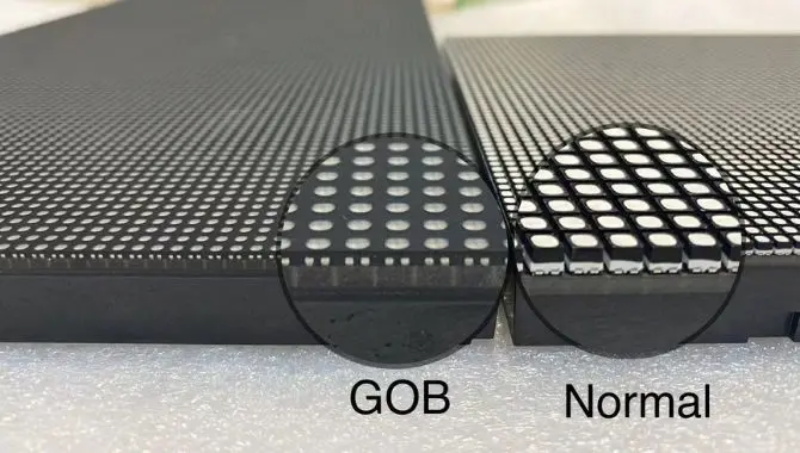

GOB (Glass-on-Board) LED Screen:

GOB technology encapsulates the LED module in a transparent epoxy resin or similar material on a PCB (Printed Circuit Board).

This encapsulation enhances the durability and protects the LEDs from environmental factors.

GOB screens are typically used in outdoor and rugged environments where protection against moisture, dust, and physical impact is necessary.

Key Differences:

Size and Pixel Density: SMD LEDs are smaller and allow for higher pixel density compared to DIP LEDs.

Color Accuracy and Viewing Angles: SMD LEDs generally offer better color accuracy and wider viewing angles than DIP LEDs.

Brightness and Power Efficiency: DIP LEDs can be brighter but consume more power compared to SMD LEDs.

Application: SMD LEDs are more commonly used indoors and for high-resolution screens, while DIP LEDs are favored for outdoor and large-scale displays where brightness is crucial. COB and GOB technologies cater to specific needs for durability and specialized applications.

Choosing between these technologies depends on factors like the intended use (indoor vs. outdoor), desired resolution, viewing angles, and environmental conditions where the LED screen will be deployed.